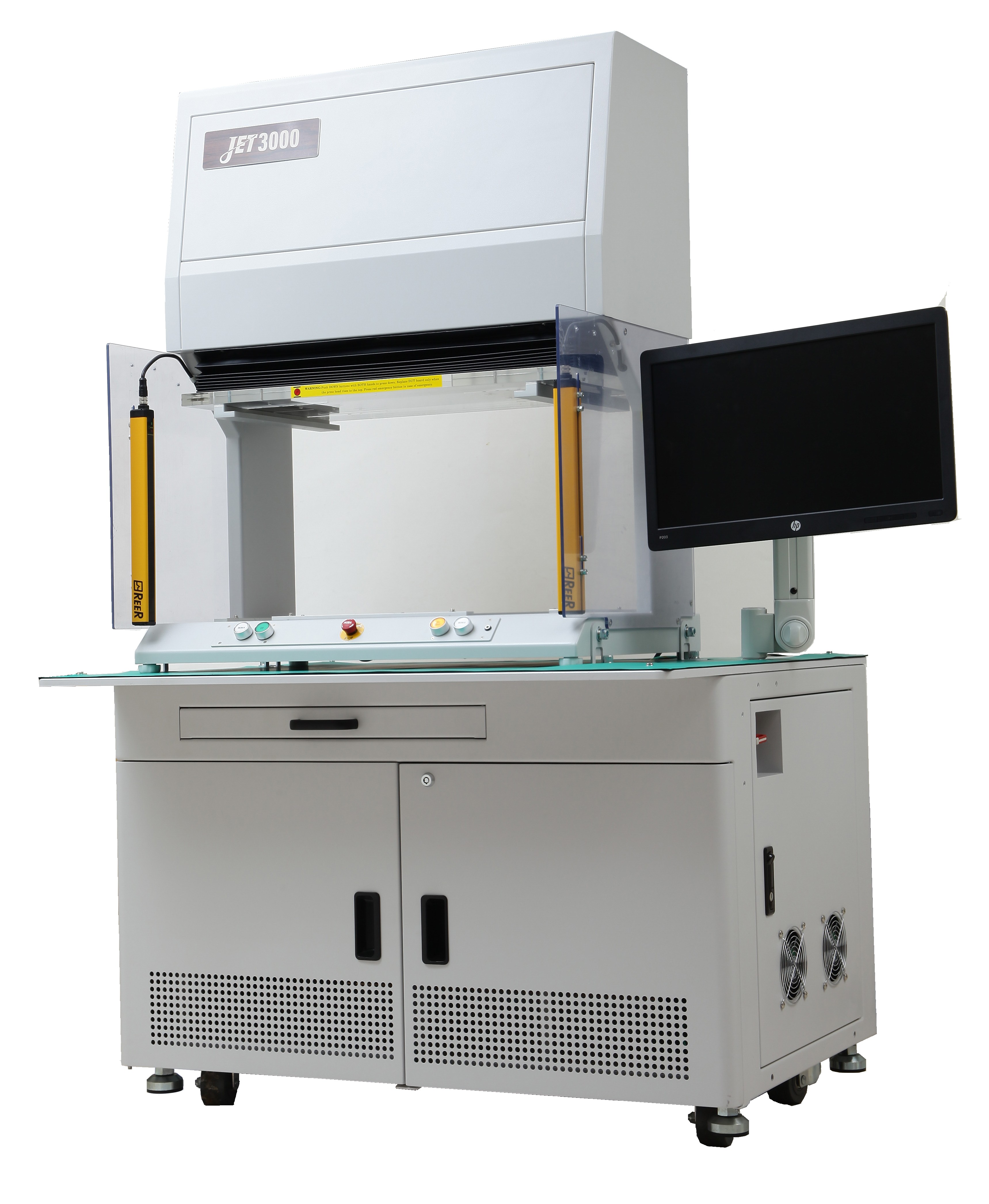

JET-3000 is a Manufacturing Defect Analysis tester, which measures the impedance of all electronic components on a Assembled PCB. First it checks for any shorts or opens which can happen in the PCB assembly Process and then goes on to test various component like (R) resistors, (C) capacitors, (L) inductors, Diodes, Transistors, FET, SCR, Zener, LED, etc.

COMPACT NEXT> LINE is the new configurable and customizable test platform for in-line or manual automated In Circuit Test (ICT), flash programming, functional/EOL and Run-in test.

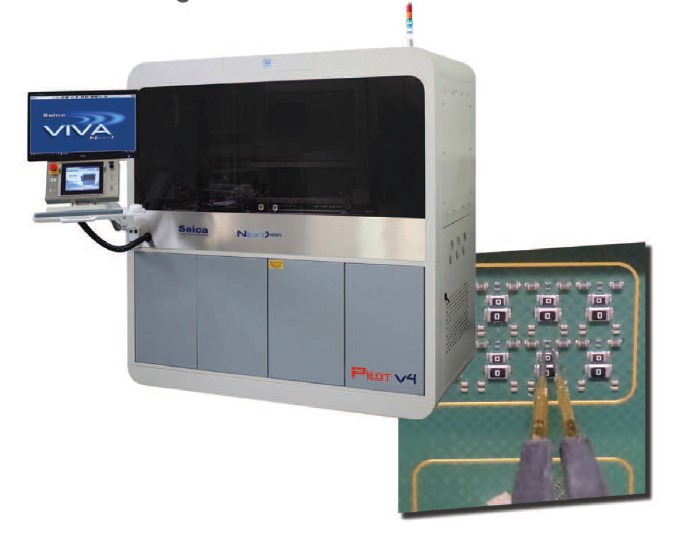

PILOT NEXT> LINE is the new generation of Seica solutions for flying probers with a sleek, modern look and the most innovative technology around. This is the new generation of flying probers featuring a renovated and sleek look thanks to the premium materials of the chassis, and innovative electrical worth discovering performances, undoubtedly the

The increasing demand from the Electric Vehicles (EV) battery industry for electric cars has changed the high-volume production battery arrays test. To meet the most complex technical needs, Seica has designed and developed the PILOT BT flying probe, the latest addition to the NEXT> Series, which is a validated, verified and completely automated system to

JTAG Testers JTAG (Joint Test Action Group) finalized the IEEE 1149.1 Standard which is popularly known as JTAG Standard or the Boundary Scan Standard with the purpose of providing an easy way to test complex boards with a lot of digital discrete component as well as other high pin count IC’s by accessing only 4/5

FlashRunner: FlashRunner is a universal, production In-System Programmer. It is the result of many years of experience in developing programming and debugging solutions for microcontrollers. FlashRunner has been carefully designed to be: • Universal – Supports multiple device manufacturers • Fast – Reduced programming time means reduced production costs • Flexible – Can be applied

Fixtures for ICT We provide Test Fixtures for all types of ICT along with the Test Programs HP/Agilent, Teradyne, Genrad, Seica, JET etc. Fixtures can be Vacuum and pneumatic Single stage as well as Dual Stage Fixtures ICT Fixtures are developed from the CAD data of the PCBA. Please contact us with your UUT data

ElectroSolve provide Functional Test /EOL Test Solutions to various applications. We provide support in choosing the hardware platform for the implementation as well as supply of the same along with the software development as per the customer requirements. The Customer Test requirements are first studied and an appropriate Test Platform is suggested for implementation of

Elogger™ Strain Measurement System Printed Wiring Board Strain Testing Strain testing allows objective analysis of the strain and strain rate levels that a SMT package is subjected to during PWB assembly, test and operation. The Elogger™ Strain Measurement System is a special design for printed wiring board strain testing application, the real-time data provided by

Universal Cable Harness Tester 128/256/512 Test Points Key Features: • 128/256/512 testing points • Open/Short/Conductance Tests • Resistance /Capacitance/Diode Test between points • Number of test file setup up to 500 sets • Multiple DUT testing-4 Cables (standard) • Identify the defective step of sequential multiple DUT test • Automatically identify the normal or reverse

3D Optical Video Inspection Microscope-HDMI 3D-SVM range of microscopes features very high quality optical systems which produce low distortion, high resolution images with a large and high depth field of view. The specialty of the lens is such that they are Parfocal in nature. This unique design with Parfocal lens make it technologically a superior

AV 862 Series have been enhanced with Image Base and Algorithm Analysis for more precise inspection. Improved structure and hardware for operation stability, speed, user friendly, quality control and productivity.

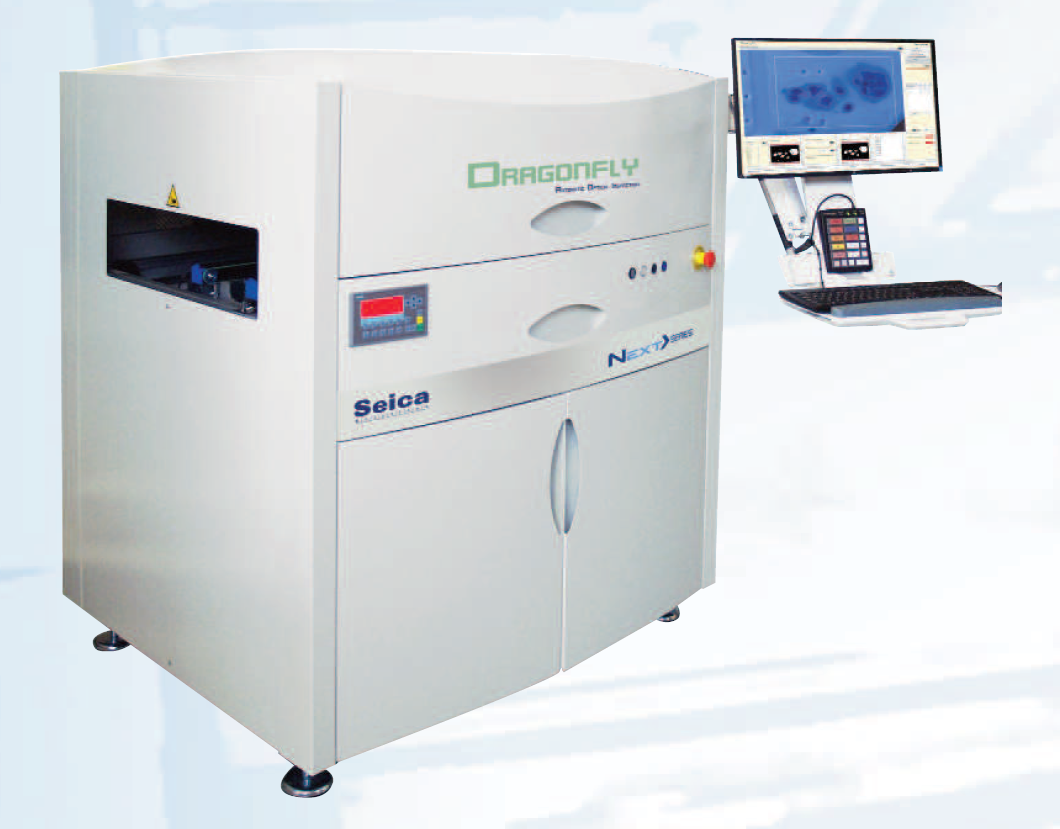

The Dragonfly CC NEXT>SERIES ensures a quick and complete examination of all coated assemblies. The combination of multi-colored LED lighting, UV-LED lighting with the color line scan camera enables clear Laquer Inspection. The full-scan imaging of the PCB will ensure proper detection of faults. Compared to manual inspection, the results of Dragonfly CC NEXT>SERIES are

2D CAMERA – SOLDER HEIGHT INSPECTOR Features and benefits Easy to use system with windows software. Laser based inspection method. High quality Mega pixel digital camera provides higher dynamic range. Inspect Thickness, Length, Width, Area and Volume, Upper and Lower limit for the measurement can be set and can be used in production. Can be

Firefly NEXT> ——— LASER SELECTIVE SOLDERING SYSTEMS After many years of development and several installations worldwide, the Firefly line has completely redesigned its architecture, taking a major step forward and setting the way for the NEXT> generation generation. DIVERSE SOLUTIONS The soldering head, which is the core of the system, is common to both